French Aerospace Manufacturer, Latécoère, Accelerates Design Validation and Tool Production with Stratasys Additive Manufacturing

-

95% reduction in prototype lead times using Stratasys’ Fortus 450mc

Production 3D Printer in place of CNC machining -

Manufacture of production tools reduced from six weeks to just two

days, while tool production costs slashed by 40%

MINNEAPOLIS & REHOVOT, Israel–(BUSINESS WIRE)–Stratasys

(Nasdaq:SSYS), a global leader in applied additive technology solutions

today announced that French aircraft design and manufacturing group, Latécoère,

is deploying Stratasys FDM additive manufacturing throughout its design

and production process, accelerating the development process and

improving business performance.

Faced with lengthy lead-times and costly design iterations, Latécoère –

which services aerospace giants including Airbus, Bombardier and

Dassault – is using its Stratasys Fortus 450mc Production 3D Printer for

both rapid prototyping and production tooling. According to Simon Rieu,

Composite and Additive Manufacturing Manager at Latécoère’s R&D and

Innovation Center, the adoption of this technology has been

transformational for both design and manufacturing.

“Additive manufacturing has integrated seamlessly into our design and

production process, and has seen us enjoy improved lead-times, reduced

costs and enhanced operational efficiency,” he says. “As the

requirements of the aerospace industry become more demanding, we’re also

mindful of the need to maintain our competitive edge, and Stratasys

additive manufacturing enables us to meet that objective.”

Accelerating Design Validation

Traditionally, the company uses CNC machining for rapid prototyping, but

this has presented limitations. “We recently produced a 3D printed

prototype to verify the fit and function of a part for the interior

lining of an aircraft door,” explains Rieu. “Previously, this would have

been made from sheet metal – an often-time-consuming process. With our

Fortus 450mc 3D Printer, we produced a fully-functional prototype in two

days, reducing our lead times by a staggering 95%. Crucially this has

accelerated our design validation process before committing to costly

and time-consuming tooling.”

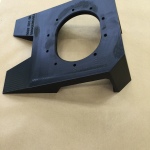

Latécoère recently 3D printed a prototype camera case for the Airbus

A380 aircraft for design validation with the camera’s internal parts

housed inside. Prior to Stratasys FDM 3D additive manufacturing, the

team would have been forced to directly manufacture an aluminum camera

case for testing, with any design iterations proving costly. Using ULTEM

9085 material, the 3D printed prototype is also 50% lighter than its

metal counterpart, enabling more efficient functional part testing.

Enhancing production tooling

The company is also utilizing its Fortus 450mc 3D Printer for the

on-demand manufacture of customized production tools. This has not only

seen significant reductions in time and cost, but also enhanced operator

efficiency.

“Using metal sheet manufacturing, creating a tool can take up to six

weeks. Now we can 3D print a tool in just two days and 50% lighter using

ULTEM 9085 material,” says Rieu. “With our 3D printer, we can also

optimize the geometry of the tool to perfectly fit the part – making the

operator’s job much easier. Not only has this accelerated our production

process dramatically, but I also estimate that we’ve reduced our tool

production costs by a massive 40%.”

Final flight-ready 3D printed production parts

Looking ahead, Latécoère’s long-term strategy is to 3D print final

production parts for next generation airplanes from the likes of Airbus,

Boeing, and other leading aircraft manufacturers. Indeed, the company

has already begun exploring the potential to utilize its Fortus 450mc to

produce final interior aircraft parts with certification in mind. Using

Stratasys’ tough, lightweight and FST compliant ULTEM 9085 material, the

team has 3D printed various air duct housing components, which has seen

significant weight reductions and time savings compared to traditional

production methods.

Andy Middleton, President of EMEA, Stratasys, concludes, “Latécoère,

like many of our aerospace customers, are benefiting from our proven FDM

technology and high-performance materials for this industry. Our

application-driven approach enables us to have a close interface with

our customers to develop solutions optimized for their design and

production processes. Whether it’s accelerating design validation or the

on-demand production of lightweight manufacturing tools, or even 3D

printed interior aircraft parts, we are committed to ensuring our

customers are given the right tools to optimize the use of additive

manufacturing.”

About Stratasys

Stratasys (NASDAQ: SSYS) is a global leader in applied additive

technology solutions for industries including Aerospace, Automotive,

Healthcare, Consumer Products and Education. For nearly 30 years, a deep

and ongoing focus on customers’ business requirements has fueled

purposeful innovations—1,200 granted and pending additive technology

patents to date—that create new value across product lifecycle

processes, from design prototypes to manufacturing tools and final

production parts. The Stratasys 3D printing ecosystem of solutions and

expertise—advanced materials; software with voxel level control;

precise, repeatable and reliable FDM and PolyJet 3D printers;

application-based expert services; on-demand parts and industry-defining

partnerships—works to ensure seamless integration into each customer’s

evolving workflow. Fulfilling the real-world potential of additive,

Stratasys delivers breakthrough industry-specific applications that

accelerate business processes, optimize value chains and drive business

performance improvements for thousands of future-ready leaders around

the world.

Corporate Headquarters: Minneapolis, Minnesota and Rehovot, Israel.

Online at: www.stratasys.com,

http://blog.stratasys.com and

LinkedIn.

Stratasys is a registered trademark and Fortus and Stratasys signet

are trademarks or registered trademarks of Stratasys Ltd. and or its

subsidiaries or affiliates. All other trademarks belong to their

respective owners.

Attention Editors, if you publish reader-contact information, please use:

- USA 1-877-489-9449

- Europe/Middle East/Africa +49-7229-7772-0

- Asia Pacific +852 3944-8888

Contacts

Stratasys Media Contacts

Stratasys

Joe Hiemenz,

+1-952-906-2726 (US)

joe.hiemenz@stratasys.com

or

Greater

China, Southeast Asia, ANZ, and India

Alison Yin,

+86-21-33196051

alison.yin@stratasys.com

or

Brazil

GPCOM

Clezia

Martins Gomes, +55 (11) 3129 5158

clezia@gpcom.com.br

or

North

America

Stratasys

Craig Librett, +1-518-424-2497

Craig.Librett@stratasys.com

or

Japan

and Korea

Stratasys Japan

Aya Yoshizawa, +81 90 6473 1812

aya.yoshizawa@stratasys.com

or

Europe

Incus

Media

Jonathan Wake / Miguel Afonso, +44 1737 215200

stratasys@incus-media.com

or

Mexico,

Central America, Caribe and South America

Stratasys Mexico

Yair

Canedo, +52 55 4169 4181

yair.canedo@stratasys.com