EnvisionTEC Now Offers Highest Resolution Large-Frame 3D Printer

-

Hardware update allows EnvisionTEC to deliver XY resolution of 25

microns in its largest laser-based 3D printers -

EnvisionTEC’s unique 3SP technology continues to win over new users,

including aftermarket wheels manufacturer Design Infini -

Launched in 2013, 3SP technology has been used reliably for years by

dental and orthodontic laboratories for volume production of dental

models

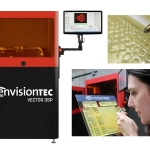

DEARBORN, Mich.–(BUSINESS WIRE)–#3dprinting–EnvisionTEC, a leading global manufacturer of desktop and

full-production 3D printers and materials, today revealed a hardware

update to its family of large-frame 3D printers that allows them to

deliver best-in-class resolution.

EnvisionTEC will now offer XY resolution of 25 microns ― equivalent to

about half the cross-section of a human hair — in two of its largest 3D

printers:

-

The Vector UHD 3SP, with a build area of 300 x 200 x 275 mm (11.8 x

7.9 x 10.8 in.) -

The Xede UHD 3SP, with a build area of 457 x 457 x 457 mm (18 x 18 x

18 in.)

The improved performance is made possible with a new FPGA

(field-programmable gate array) control that allows EnvisionTEC to turn

its laser on and off in the Y scanning direction with lightning-fast

speed.

“With this hardware upgrade, EnvisionTEC can now offer the same level of

resolution in our 3SP family that we are known for with our Perfactory

printer family,” said CEO Al Siblani.

A demonstration board 3D printed on a Vector UHD 3SP will be on display

this week in Fort Worth, Texas, at Rapid + TCT, the premier event for 3D

manufacturing in North America. EnvisionTEC will also be showcasing

other new 3D printer and material innovations in Booth 1304.

The recent hardware upgrade makes 3SP printers an ideal choice for

applications requiring high accuracy, fine detail or ultra-smooth

surfaces, such as medical devices, parts with fluidic chambers, tooling

for molds, large investment casting patterns and detailed prototypes.

About 3SP Technology

Launched in 2013, EnvisionTEC’s patented 3SP (Scan, Spin and Selectively

Photocure) technology uses a unique laser-based process to cure

photopolymers in a large vat.

While conventional SLA systems use an expensive solid state laser to

draw out parts layer by layer, often reflecting the beam off galvo

mirrors in a large build area, the 3SP approach is simple and efficient.

A multi cavity diode laser is reflected off a spinning mirrored drum

that can efficiently scan across a very large vat to cure material.

Essentially, the laser draws in straight lines in the Y direction, with

the beam simply turning on or off to cure the necessary shape as the

complete laser assembly moves in the X direction.

A white paper detailing how 3SP is superior to SLA for manufacturing and

production can be found at EnvisionTEC.com/learn3SP.

Adoption of 3SP continues to grow as knowledge about the technology and

portfolio of materials expands. The 3SP line is popular among dental

laboratories printing large volumes of dental models, but users also

include manufacturers in a variety of industries, including medical

devices, automotive, aerospace, consumer goods and more.

About EnvisionTEC

EnvisionTEC is a leading global provider of professional-grade 3D

printers and materials. Founded in 2002 with its pioneering commercial

DLP printing technology, EnvisionTEC now sells 3D printers based on six

distinct technologies that build objects from digital design files. The

company’s premium 3D printers serve a variety of medical, professional

and industrial markets, and are valued for accuracy, surface quality,

functionality and speed. EnvisionTEC’s intellectual property includes

more than 140 pending and granted patents. Learn more at EnvisionTEC.com.

Contacts

EnvisionTEC

Sarah A. Webster, +1-313-888-4460

swebster@envisiontec.com